We have the capability to manufacture :

- MCC/PCC Panels for Industrial Plant Application,

- ETP/STP PLC Systems and Plant Setup.

- LPBS, Stacker/Reclaimer panels in Cement Plants.

- LT Distribution panels and DB.

- DG Synchronization Panels with PLC & With Synchronization Relays.

- AMF & LMS Panels.

- APFC Panels.

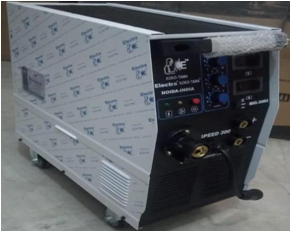

- VFD Panels.

- PLC/DCS Panels.

- Control Desk for plants.

- Automatic Panels.

- Air Conditioned Process Panels.

- HT Panel upto 33KV Supply and commissioning.

All our panel designs are fully modular and foldable types confirming to IP-

42,55,65(On Demand only), Third party IP Certification facility is also available.